¥25,190

japanese knife

There are 82 products.

Japanese Sakimaru Takobiki Knife - SAKAI TAKAYUKI - Byakko - shirogami 1 - Size:27/30cm

Product available with different options

¥29,040

¥14,300

¥15,400

¥30,630

¥28,490

¥22,440

Japanese chef knife - Gyuto - Glestain - Size:21 / 24 / 27 / 30cm

Product available with different options

Tempo para ser despachado : 2 a 3 dias após confirmação de pagamento

¥26,400

Japanese Mukimono Knife - Sakai Takayuki ‐ carbon white steel No.3 - Kasumi Finish - 18cm

Out-of-Stock

"Sakai Takayuki" is a brand owned by Aoki Hamono, a major manufacturer in Sakai City, Osaka Prefecture, who has been promoting the sharpness of Japanese kitchen knives not only in Japan but also in Europe, the United States, Asian countries, Central and South America, and the Middle East.

The lineup includes knives for cooking, confectionery, ice carving, etc. Their flagship, Japanese single bevel knives are all first-class products made by traditional craftsmen in Sakai.

The lineup includes knives for cooking, confectionery, ice carving, etc. Their flagship, Japanese single bevel knives are all first-class products made by traditional craftsmen in Sakai.

Chinese Cleaver - SAKAI TAKAYUKI - Stainless VG10 - Damascus - Hammered - Size : 19.5cm

Out-of-Stock

"Sakai Takayuki" is a brand owned by Aoki Hamono, a major manufacturer in Sakai City, Osaka Prefecture, who has been promoting the sharpness of Japanese kitchen knives not only in Japan but also in Europe, the United States, Asian countries, Central and South America, and the Middle East.

The lineup includes knives for cooking, confectionery, ice carving, etc. Their flagship, Japanese single bevel knives are all first-class products made by traditional craftsmen in Sakai.

The lineup includes knives for cooking, confectionery, ice carving, etc. Their flagship, Japanese single bevel knives are all first-class products made by traditional craftsmen in Sakai.

¥39,710

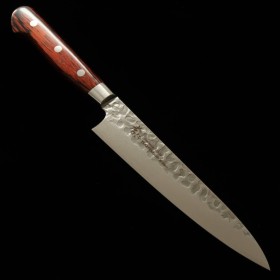

Japanese Petty Kife - SAKAI TAKAYUKI - VG10 33layers Damascus Stainless Steel hammered - Size: 15cm

Out-of-Stock

"Sakai Takayuki" is a brand owned by Aoki Hamono, a major manufacturer in Sakai City, Osaka Prefecture, who has been promoting the sharpness of Japanese kitchen knives not only in Japan but also in Europe, the United States, Asian countries, Central and South America, and the Middle East. The lineup includes knives for cooking, confectionery, ice carving, etc. Their flagship, Japanese single bevel knives are all first-class products made by traditional craftsmen in Sakai.

¥15,840

¥22,400

Japanese Kirituke Yanagiba Knife - SAKAI TAKAYUKI - Grand Chef series - Stainless steel - Black Seath - size: 26cm

Out-of-Stock

"Sakai Takayuki" is a brand owned by Aoki Hamono, a major manufacturer in Sakai City, Osaka Prefecture, who has been promoting the sharpness of Japanese kitchen knives not only in Japan but also in Europe, the United States, Asian countries, Central and South America, and the Middle East.The lineup includes knives for cooking, confectionery, ice carving, etc. Their flagship, Japanese single bevel knives are all first-class products made by traditional craftsmen in Sakai.

¥42,460

Japanese Honyaki Gyuto Knife - RED ORCA - Carbon Blue Steel No.2 - Ebony wood Octagon Handle with Silver Ring - size:24cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

Japanese Honyaki Funayuki knife - RED ORCA - Carbon Blue Steel No.2 - Ebony wood Octagon Handle with Silver Ring - size:18cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

Japanese Honyaki Honesuki Knife - RED ORCA - Carbon Blue Steel no.2 - Ebony wood with Silver Ring - size: 16cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Koufuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Koufuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Koufuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Koufuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.