japanese knife

There are 33 products.

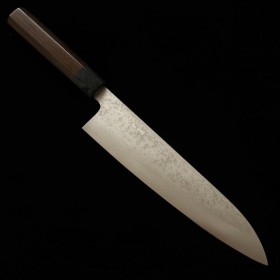

Japanese Santoku knife - MAKOTO KUROSAKI - Kodama series - Stainless VG10W - Damascus - Zelkova wood handle - Size : 17cm

Last items in stock

These knives are made by Makoto Kurosaki, the big brother of the world-famous Yu Kurosaki. He is a professional knife sharpener.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

¥34,540

Japanese Petty knife - KUROSAKI MAKOTO - Stainless VG7 - Damascus - Ebony wood handle - Size : 13.5cm

Out-of-Stock

These knives are made by Makoto Kurosaki, the big brother of the world-famous Yu Kurosaki. He is a professional knife sharpener.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

¥24,420

Japanese Chef knife Gyuto - MAKOTO KUROSAKI - Stainless VG7 - Damascus - Ebony wood handle - Size : 21cm

Out-of-Stock

These knives are made by Makoto Kurosaki, the big brother of the world-famous Yu Kurosaki. He is a professional knife sharpener.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

¥31,460

Japanese Chef knife Gyuto - MAKOTO KUROSAKI - Style-K series - Stainless SG2 - Hammered - Sakura Handle - Size : 24cm

Out-of-Stock

These knives are made by Makoto Kurosaki, the big brother of the world-famous Yu Kurosaki. He is a professional knife sharpener.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them

¥30,140

Japanese Slicer knife Sujihiki - MAKOTO KUROSAKI - Style-K series - Stainless SG2 - Hammered - Sakura Handle - Size : 27cm

Out-of-Stock

These knives are made by Makoto Kurosaki, the big brother of the world-famous Yu Kurosaki. He is a professional knife sharpener.

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them

His knives are finely crafted, thinly finished, and provide a sharp cutting edge.

Their simple design harmonizes with the kitchen and gives us the pleasure of using them

¥32,780

Japanese Santoku knife - KUROSAKI MAKOTO - Stainless VG7 - Damascus - Ebony wood handle - Size : 16.5cm

Out-of-Stock

These knives are made by Makoto Kurosaki, the big brother of the world-famous Yu Kurosaki. He is a professional knife sharpener.His knives are finely crafted, thinly finished, and provide a sharp cutting edge.Their simple design harmonizes with the kitchen and gives us the pleasure of using them.

¥27,500

Japanese Honyaki Gyuto Knife - RED ORCA - Carbon Blue Steel No.2 - Ebony wood Octagon Handle with Silver Ring - size:24cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

Japanese Honyaki Funayuki knife - RED ORCA - Carbon Blue Steel No.2 - Ebony wood Octagon Handle with Silver Ring - size:18cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.