japanese knife

There are 17 products.

Japanese Petty Knife - KANIMAN KAJI KOUBOU - Leaf Spring CarbonSteel - Black Finish - Size:9cm

Out-of-Stock

"Kaniman" is an old Okinawan word meaning “blacksmith” or “one who is involved with iron.” We produce blades that fit modern life based on traditional blades from the southern islands.Steel materials are selected from scrap wood or special steel for blades depending on the blade's purpose, and handles are often made of Okinawan wood.Shima knives - knives that were used in the historical climate of Okinawa, designed to be light and short to fit modern kitchen conditions.

Japanese Honyaki Gyuto Knife - RED ORCA - Carbon Blue Steel No.2 - Ebony wood Octagon Handle with Silver Ring - size:24cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

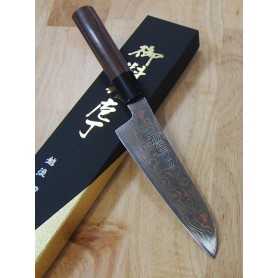

Japanese Honyaki Funayuki knife - RED ORCA - Carbon Blue Steel No.2 - Ebony wood Octagon Handle with Silver Ring - size:18cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Kofuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Kofuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

Japanese Honyaki Honesuki Knife - RED ORCA - Carbon Blue Steel no.2 - Ebony wood with Silver Ring - size: 16cm

Out-of-Stock

Kofuse-zukuri is a difficult technique that requires a high level of skill and experience, and is the same manufacturing method used for Japanese swords.

The Koufuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Koufuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

The Koufuse-zukuri method was developed in 1995 out of the desire to create something unique, something with the sharpness of forging but with the elasticity of a sword.

Conventional hammered blades are made by inserting steel into steel (steel is sandwiched between steel), but Koufuse-zukuri is the opposite: steel is inserted into steel, in other words, steel is wrapped around extremely soft iron, which serves as the core metal, in the same way as Japanese swords are made.

This highly technical and time-consuming forging process is said to be the reason why Yasugi steel is as resilient as spring steel, strong, and durable (does not chip).

Incidentally, the brand name "Red Orca" was named after Shozo Akitomo, the sales manager of the company, who is fond of orcas.

Japanese kiritsuke yanagiba Knife - SK Japan SHISUI - Stainless Steel - RWL34 - Mirrored - Honyaki - Size:30cm

Out-of-Stock

Shisui is one of the most talented craftsmen cutlers of the Japan's new generation. Although not so known abroad, Shisui has an unique talent.All your knives are polished as mirror.

¥191,950

Japanese nakiri Knife - YAMAMOTO HAMONO - Blue Steel No.2 - Sizes: 17cm

Out-of-Stock

Yamamoto Knives, located in Echizen City, Fukui Prefecture, is headed by Nao Yamamoto, an official traditional craftsman.

He is known for his skill in using both carbon steel and stainless steel to create kitchen knives with Damascus patterns and Japanese style knives in his excellent taste.

He is known for his skill in using both carbon steel and stainless steel to create kitchen knives with Damascus patterns and Japanese style knives in his excellent taste.

Japanese slicer sujibiki Knife - YAMAMOTO HAMONO - Blue Steel No.2 - Sizes: 24 / 27cm

Out-of-Stock

Yamamoto Knives, located in Echizen City, Fukui Prefecture, is headed by Nao Yamamoto, an official traditional craftsman.

He is known for his skill in using both carbon steel and stainless steel to create kitchen knives with Damascus patterns and Japanese style knives in his excellent taste.

He is known for his skill in using both carbon steel and stainless steel to create kitchen knives with Damascus patterns and Japanese style knives in his excellent taste.

Japanese Chef Gyuto Knife - YAMAMOTO HAMONO - Blue Steel No.2 - Sizes: 21 / 24cm

Out-of-Stock

Yamamoto Knives, located in Echizen City, Fukui Prefecture, is headed by Nao Yamamoto, an official traditional craftsman.He is known for his skill in using both carbon steel and stainless steel to create kitchen knives with Damascus patterns and Japanese style knives in his excellent taste.