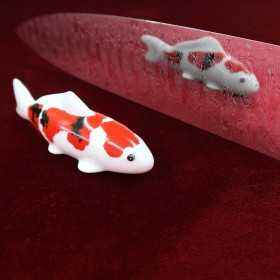

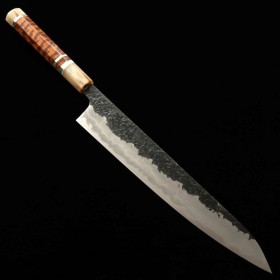

Japanese Chef Knife Gyuto - KISUKE【ENN】‐MANAKA - Blue Carbon Steel No.1 - Black Damascus Finish - size: 24cm

Last items in stock

"Kisuke" is a completely handmade kitchen knife produced by Shunsuke Manaka, the fifth generation of Manaka Hamono.

He has not only inherited the traditional techniques, but has also researched the steel from a scientific point of view to create his own unique style.

The materials used for the knives are not limited to the traditional Shirogami and Aogami, but also include a wide range of stainless steels and high performance powder steels, and are finished with a calculated heat treatment.

The powerful Kisuke kitchen knives with extremely sharp cutting ability are excellent products that we can recommend with confidence.

He has not only inherited the traditional techniques, but has also researched the steel from a scientific point of view to create his own unique style.

The materials used for the knives are not limited to the traditional Shirogami and Aogami, but also include a wide range of stainless steels and high performance powder steels, and are finished with a calculated heat treatment.

The powerful Kisuke kitchen knives with extremely sharp cutting ability are excellent products that we can recommend with confidence.